Cost-Efficient Solution for Corrosion Mapping Capital Assets

Ask an expertAnyone operating in the non-destructive testing industry understands that more than one tool is required for inspection. Even with similar applications, certain variables can impact coverage. It is common for an inspector to encounter a variety of critical components and infrastructure requiring condition assessments in one job. Regardless of the unique conditions for the range of assets requiring inspection, it is imperative that the inspection data results are repeatable, actionable, meaningful, and preventative. To consistently meet this goal, industry should seek a trusted equipment solutions provider dedicated to supplying clients and stakeholders with a turnkey solution that supports application deliveries.

The Challenge

Find a cost-effective solution that can cover a broad range of phased array corrosion mapping requirements.

Technicians performing phased array corrosion mapping on vessels, dome ends, and associated pipework have to contend with a number of challenges including varying wall thicknesses, multiple diameter pipelines, restricted access, as well as non-uniform component configuration. Multiple devices are necessary in order to collect the accurate data essential for effective and efficient risk management programs. With these considerations in mind, it is obvious that the financial burden of acquiring powerful and dependable equipment may pose a challenge in itself. It is therefore imperative for those operating in the non-destructive testing sector to research synergistic hardware and software solutions that maximize utilization through multifunctionality for greater cost effectiveness.

The Solution

New and improved commercial technology offered in turnkey package provides complete coverage of assets.

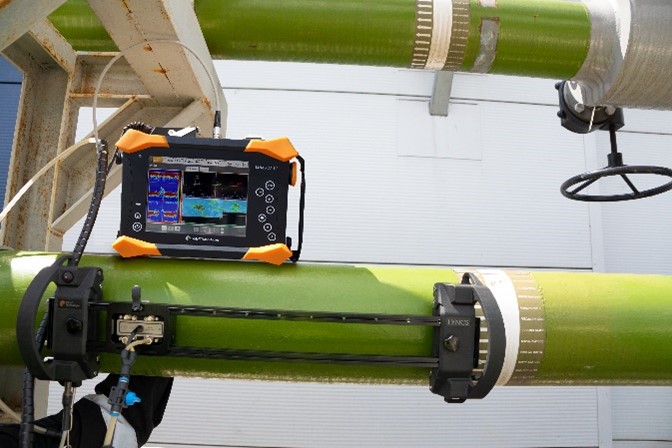

Originally released in 2019, the R-Scan Array was developed to provide phased array corrosion mapping with the popular RMS automated scanner by Eddyfi Technologies. With integrated electronics for data acquisition and stitching, an ergonomic handle, and interchangeable low and high friction wheels, the commercially available solution is the first choice for single person operations. Following positive feedback from equipment users worldwide, it was clear that the R-Scan Array could easily provide a cost-effective corrosion mapping solution in its own right following some design improvements. The optimized version based on recommendations from extensive field use enhances the user performance for both automated inspection with the RMS scanner as well as in a manual capacity when connected directly to leading phased array ultrasonic testing instruments produced by Eddyfi Technologies Centers of Excellence.

Improvements include:

1. Interchangeable wheels to improve magnetic force when in manual mode

2. Enhanced probe locking mechanism

3. Integrated breaking system to help with setup, calibration, and operations.

In addition to the reformed R-Scan Array, Eddyfi Technologies introduced a new solution to the market that provides a 2-axis option for phased array corrosion mapping of pipework and vessels: the LYNCS™ CM, an innovative corrosion mapping scanner. Having two axis alongside integrated electronics and an extremely low profile, the LYNCS CM affords equipment users the most efficient manual scanner for corrosion mapping of large surface area assets like pressure vessels.

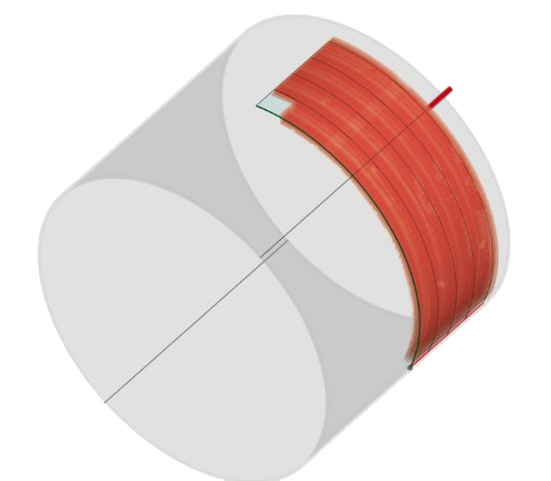

The LYNCS CM is extremely flexible and includes numerous bar lengths that can be adjusted to overcome restrictions encountered at pipe supports and welds. When inspecting vessels, however, there is a requirement for increased scanning dexterity when examining around nozzle attachments, compensation pads, and most importantly, the dome ends. This is where the R-Scan Array can supplement the inspection scope. Eddyfi Technologies’ bundled corrosion mapping solution allows clients to scan large straight sections with LYNCS CM and then simply unclip and place the phased array probe, water box, and seal in the R-Scan Array cradle to complete corrosion mapping of the more complex locations. This is truly an industry first, complete manual phased array corrosion mapping system.

Ask an ExpertR-Scan Array on Pressure Vessel Dome End

LYNCS CM for Straight Pipework Inspection

Benefits

- Software enables assisted defect analysis while shared hardware components extend higher return on investment.

The new and improved R-Scan Array increases manual operation performance, and when combined with LYNCS CM 2-axis scanner, this turnkey inspection solution maximizes coverage, improves dexterity, and reduces dead zones. By sharing components, this is the most cost effective and complete corrosion mapping package available on the market today.

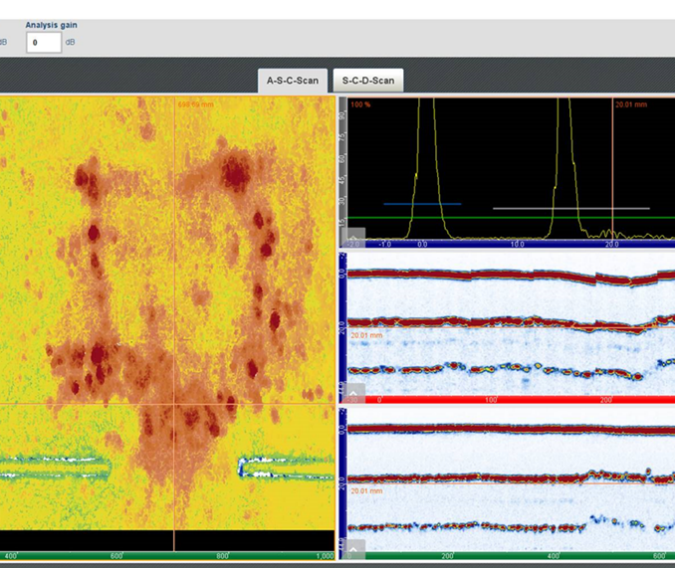

All of these ergonomic and cost efficiency improvements are a great compliment to Capture™ acquisition and analysis software embedded on the Gekko® and Mantis™ portable phased array ultrasonic testing instruments. Operators have assisted defect analysis tools to instantly locate areas of wall loss, automate remaining thickness measurements, and provide a 3D map of the areas that have been scanned.

Eddyfi Technologies presents a unique, symbiotic product offering that leverages advanced technologies from its many centers of excellence to provide the inspection solutions that are trusted to deliver all the data necessary for proactive asset health management programs. Contact us to discuss optimizing your operations today.