Inspecting Turbine Dovetails with Eddy Current Array Technology

Gas turbines are critical assets in the power generation sector. They are large and complex, and shutting them down is often quite costly. The blades in these turbines are generally attached to the rotor through an ingenious system of male and female “dovetails”. These dovetails must be inspected for defects with great efficiency to ensure safety and to maximize the life of the equipment, often in the context of life extension programs.

The Challenge

- Efficiently inspect gas turbine dovetails for minute cracking, extending the life of aging equipment.

Dovetails are especially prone to fatigue cracking and Stress-Corrosion Cracking (SCC), which is defined as the growth of cracks in a corrosive environment. If left unchecked, SCC can lead to unexpected failure of normally ductile metals (e.g., INCONEL®) subjected to tensile stress, such as is the case in gas turbines.

The cracking of interest here is typically small and concentrated near dovetail hooks. Conventional eddy current pencil probes and Penetrant Testing (PT) were used for a number of years with very limited success. The specific geometries of dovetails make inspection with these methods unreliable, if at all possible.

Of the two dovetail parts, inspecting the female portion has proven the most time-consuming and demanding. Inspection usually involves using slow, complex, and costly robots.

Furthermore, because there are almost as many dovetail designs as there are gas turbines, a one-size-fits-all solution such as a flexible design is virtually unthinkable, especially while wanting to preserve the level of precision necessary to effectively characterize minute cracks.

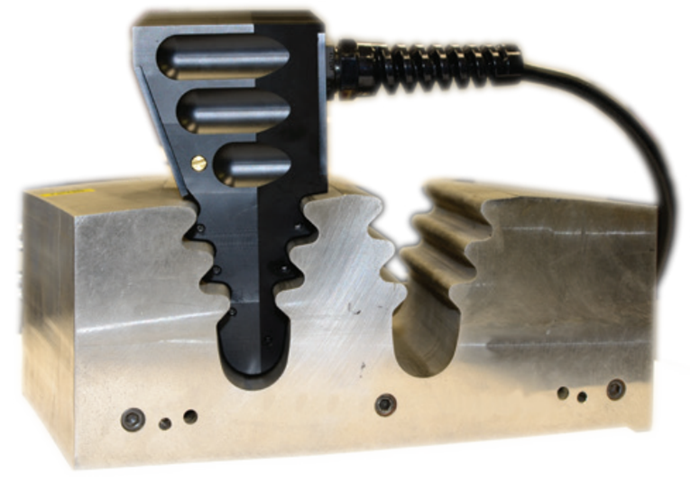

This application therefore calls for a solution that can scan female dovetails in a single pass and designed to match the dovetail’s profile.

The Solution

- ECA probes perfectly profiled to match dovetail geometries.

Because dovetails vary greatly in shape and size, they usually require a custom solution. The Eddy Current Array (ECA) technology in the probe remains nonetheless the same.

To scan a wide inspection area, ECA technology uses multiplexing. That is, several individual coils are grouped together in one probe and excited sequentially to eliminate interference from mutual inductance. The coils are designed to have the necessary impedance and penetration level for accurate inspection.

Moreover, the coils are mounted inside a thin (0.25 mm or 9.8 mil), spring-loaded and durable membrane, guaranteeing constant contact with the dovetail. The shape of the probe also makes it very stable and easy to handle, eliminating the need for expensive robotic solutions.

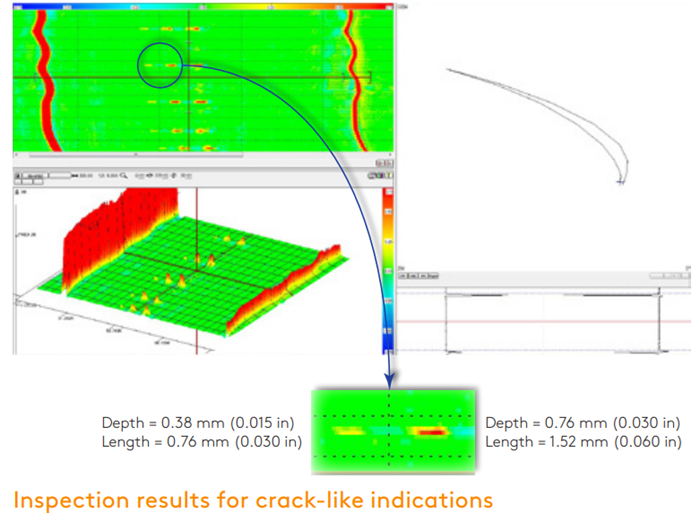

Furthermore, the custom dovetail probe is equipped with precision encoders, which allow locating and length-sizing defects in space when analyzing 2D and 3D C-scans with the Eddyfi® Magnifi® high-performance software. It is also capable of computerized record keeping and reporting, which are great advantages over PT.

Driving the dovetail probe is the Eddyfi Ectane®—a compact, rugged, batteryoperated, and portable ECA data acquisition unit with an integrated multiplexer.

Actual testing on dovetail profiles demonstrates that the probe can detect defects down to 0.38 mm (0.015 in) deep and 0.76 mm (0.030 in) long.

Benefits

- A custom-fit, one-pass, single-operator solution with precise computerized data recording.

This dovetail inspection solution has several advantages over others:

Custom solution shaped to specific dovetail profiles

Custom solution designed to target your specific “hot spots” or entire dovetail profile

Rapid, single-pass scan of regions of interest

No harsh chemicals or hazardous waste

Easy to handle—no need for expensive robotic solutions

Easier interpretation with C-scan imaging

Full computerized data recording and archiving capabilities

Beyond dovetails, turbine blades, generator slots, rotor bores, and bore holes also need to be inspected regularly, quickly, and efficiently. These applications also involve designing custom probes to fulfill highly specific sets of requirements. Over the years, Eddyfi Technologies has gained a wealth of concrete experience developing eddy current array probes for these applications. By partnering with us for your turbine application requirements, you’re not starting from scratch. Rather, you have a great head start.