Features

- Complete step-by-step wizard for inspection setup

- Cloud-based licensing

- Artificial Intelligence (AI) detection for ECT tubing inspections

- Advanced signal processing and data analysis

- Collaborative connectivity tools

- Assisted analysis for all tubing techniques

Details

Multi-technology and fully customizable

Introduced in 2011, Magnifi software is used by thousands of operators worldwide for the inspection of a wide range of components. Since its first version, it has integrated several technologies and become even more versatile over time.

Advanced heat exchanger tubing inspections with:

- Eddy Current Technology ECT and Eddy Current Array ECA

- Near-Field Technology NFT and Near-Field Array NFA

- Remote-Field Technology RFT and Remote-Field Array RFA

- Magnetic Flux Leakage MFL

- Internal Rotary Inspection System IRIS

Advanced surface inspections with:

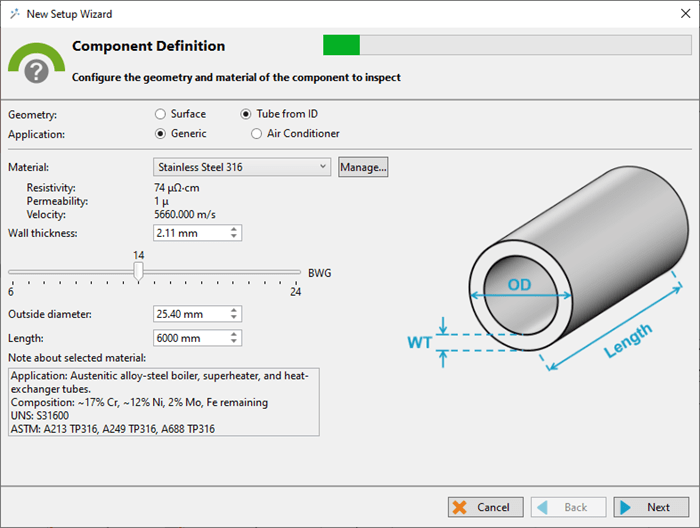

Magnifi incorporates several layouts, calibration processes, and display options to tailor parameters for the right tools for each inspection. Truly versatile, Magnifi also enables the import and creation of custom probe setups when required.

Magnifi makes it possible to use a wide variety of tools to process raw data. Technology-specific tools have also been integrated into the software such as:

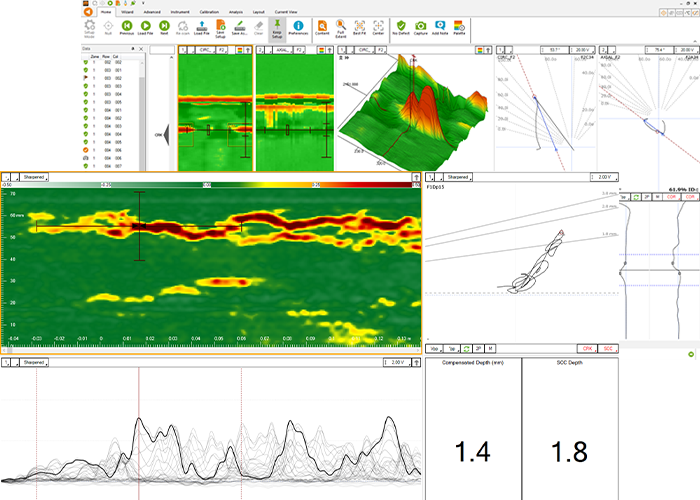

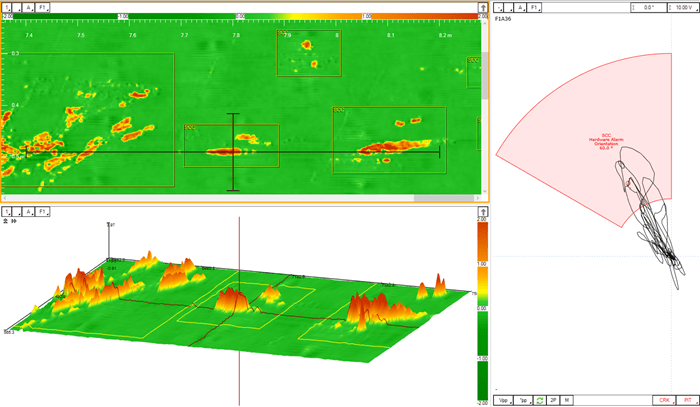

- 2D and 3D C-scans

- Real-time filters

- Automatic detection thresholds

- Sizing curves and overlays

- Superimposed channel display

- Customizable info fields

- Subtraction cursor and much more.

Latest innovations

Magnifi 5 now includes Remote-Field Array (RFA), a new technology and complete probe family dedicated to the inspection of ferrous tubing. The c-scan enables better insight on defect morphology, and the array of sensors increases detection near external features compared to conventional RFT. The first patent-pending artificial intelligence module aiming at improving efficiency and confidence in final reports is also available in Magnifi 5. This innovation also supports acquisition of higher data quality for ECT inspections.

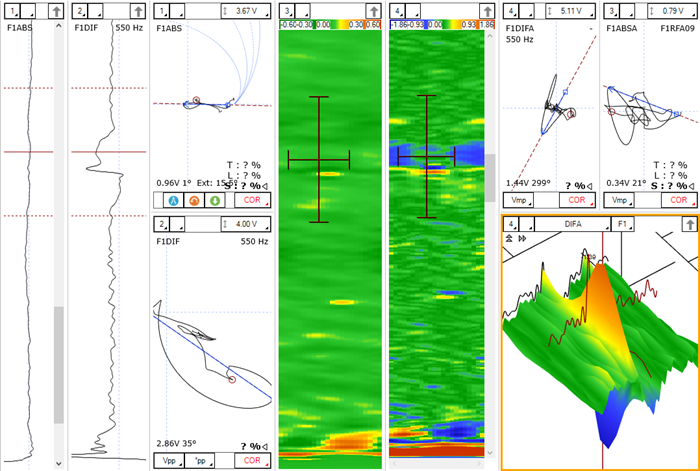

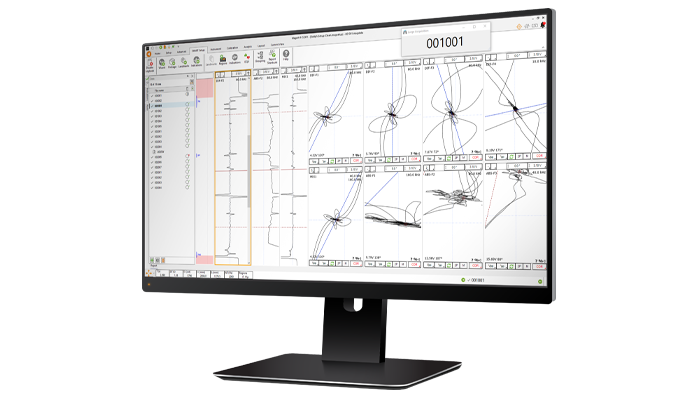

Advanced signal processing

In combination with the industry’s highest resolution probes, Magnifi incorporates 2D and 3D C-scans, making analysis more intuitive and results easier to interpret. Up to 256 raw channels can be generated by sequential coil activation and displayed at once in a single C-scan tailored to specific detection needs.

Magnifi GO on Reddy is now compatible with cloud-based data storage through Microsoft OneDrive. With one click, connect to your OneDrive account and allow the acquired data to be automatically transferred to the cloud. Analysts anywhere on the globe can get immediate access to the data, making collaborative work easier than ever before.

A thoughtful interface

Magnifi has been designed to facilitate the work of users. Its interface is modern and includes ribbons that group icons in a logical and efficient way. The software is divided into two parts: the Backstage which allows you to adjust more general settings such as preferences and file names, and the Frontstage which is dedicated to data acquisition and analysis.

Quick setup

Creating your setup can be done with the help of a step-by-step wizard. By selecting the parameters of the component that you have to inspect, the software will automatically recommend the right frequencies and filters and suggest a way to calibrate and build your calibration curves. Surface array probes are also automatically recognized by Magnifi when they are connected to the instrument, helping selecting the right setup and inspection parameters.

Automatic recording for tubing inspection

Data acquisition and recording can be activated automatically when the probe enters or leaves a tube. This allows the person acquiring the data to avoid having to activate these functions manually on the computer or on the instrument. It is also possible to display the number of tubes being scanned in large print to keep track while away from the screen.

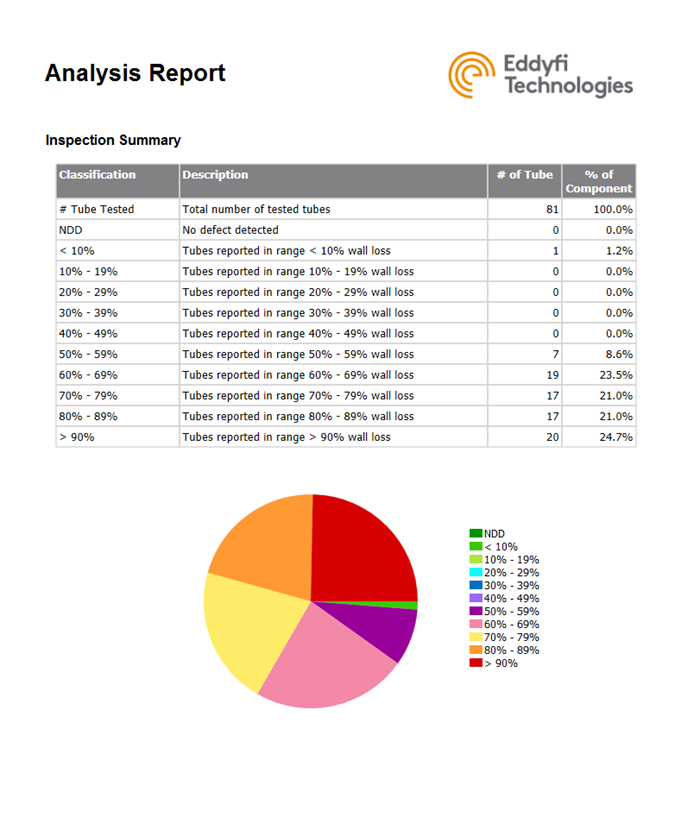

Create reports in a few simple steps

Many report templates can be selected in Magnifi and linked with the report entries made in the software. Only a few steps are necessary to generate a report with customizable fields, a picture of the component, a list of defects, insightful graphs, and the logo of your company. This makes it simple to provide a final inspection report before leaving the job site.

Keyboard shortcuts

Frequently used functions, from acquisition to analysis, can be performed using keyboard shortcuts. Magnifi 5 allows for custom keyboard shortcut configuration, such as entering the desired indication using the selected channel and measurement method.

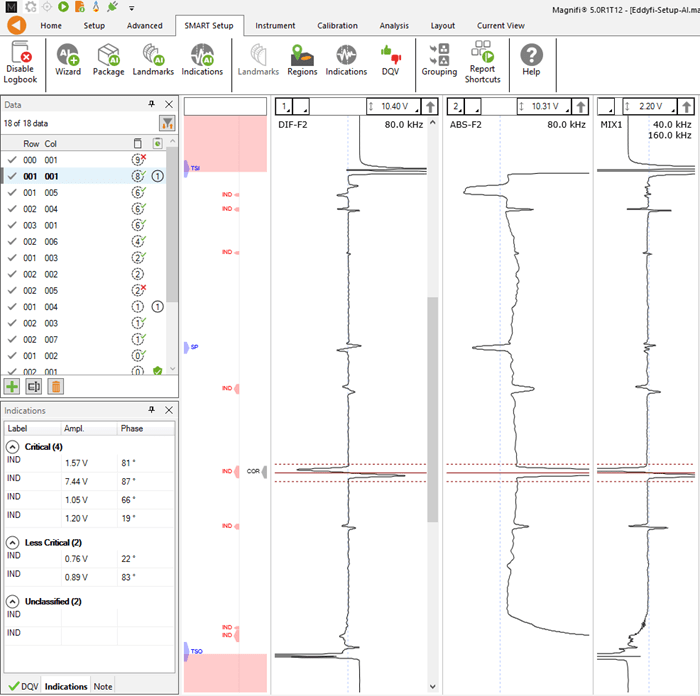

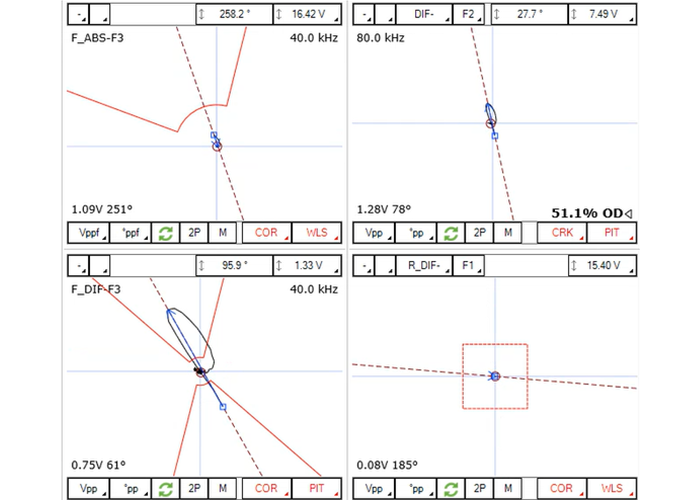

Indication detection

The Indications module allows the user to define various zones or even waveform types to trigger a detection threshold. These detection zones can be applied to conventional channels or to C-scans and can be adjusted directly on the Lissajous. For C-scans, when an indication reaches this threshold, it is automatically boxed in and displayed in a list. By clicking on the indication, the cursors are automatically adjusted for a finer signal analysis.

Introducing Artificial Intelligence (AI) for tubing inspections

The first tool of its kind for ECT tubing inspectionsArtificial Intelligence (AI) in ECT inspections

Using a patent-pending process with AI neural networks, Magnifi

automatically detects and positions cursors on tubesheets, support

plates, and defects during ECT heat exchanger tubing inspections.

Activated in a few clicks, the AI-ECT module aims to improve

confidence in the analysis and support the collection of higher

quality data. It is simple to learn and easy to use during both

acquisition and analysis.

The AI findings are the suggested potential locations of indications;

they are not intended to be an automatic reporting tool. It remains

the responsibility of a certified analyst to choose the indications

that should be reported.

Learn More

Collect Superior Data Quality

With automatic screening during acquisition, AI detection for ECT can instantly validate if the full tube length data was collected.

Assisted Analysis for all Tubing Techniques

In addition to AI-based detection, Magnifi offers a complete toolset to automatically detect landmarks and indications for:

- Eddy Current Testing ECT

- Remote-Field Testing RFT

- Remote-Field Array RFA

- Near-Field Testing NFT

- Magnetic Flux Leakage MFL

- DefHi ECA

- Near-Field Array NFA.

Using a visual representation with detection boxes, the user can easily adjust the detection parameters depending on the tube conditions.

Learn more

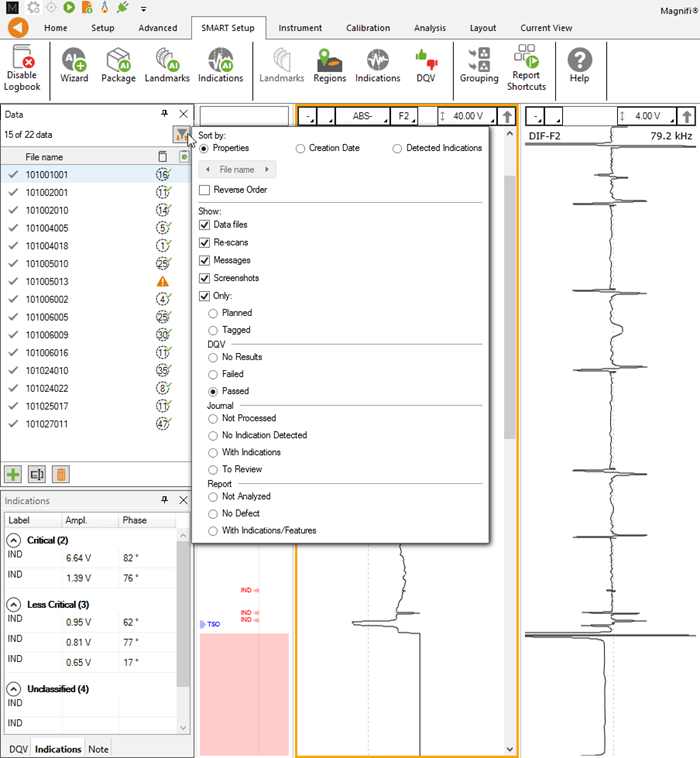

Productivity gain up to 50% on ECT data analysing

For both calibration and analysis, the benefits of AI findings are enhanced by the introduction of new tools developed to help analysts quickly find the critical information they want to report:

- The defect grouping is used to quickly identify the most relevant indications to report.

- The Tube list sorting brings tubes with the highest number of potential indications to the top,

- The filtering displays or hides categories of AI findings (no indication, with indications, DQV results, and others).

- The high precision automatic cursor positioning tool also speed up the report entry.

With the combination of these tools, an analyst performing an ECT data analysis can reduce the analysis time by approx 50% while increasing the confidence that no major defects are left behind.

A new licensing system that makes your life easier

Software licenses are now activated in seconds and can be easily shared within your teamSTD and PRO

The Standard (STD) version of Magnifi desktop supports up to five technologies in conventional modes: ECT, RFT, MFL, NFT, and IRIS. The Professional (PRO) version enables access to advanced inspections with array sensors for ECA, TECA, MFLA, and NFA. ECT acquisitions are now powered by Artificial Intelligence (AI) modules introduced in Magnifi 5.

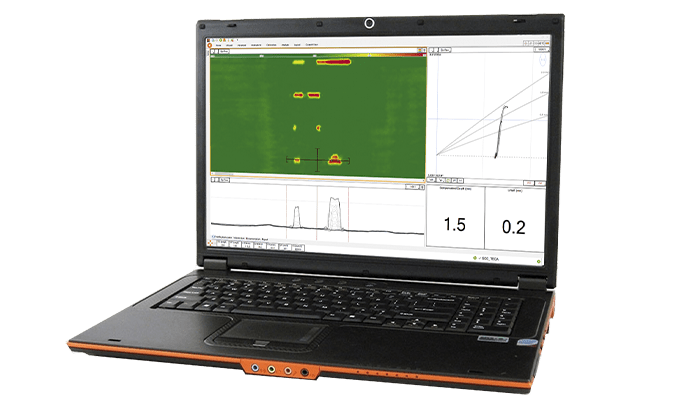

GO and GO AC

Packaged with the latest technology, the Reddy® system combines high portability with an intuitive user experience. For surface inspections with ECA and MFL array, Reddy is driven by Magnifi GO, the embedded version of Magnifi desktop. For ECT bobbin and AC tubing inspections, the Magnifi GO AC version offers integrated automated acquisition sequences and advanced analysis capabilities for on-the-fly reporting.

Magnifi GO on Reddy is now compatible with cloud-based data storage through Microsoft OneDrive. With one click, connect to your OneDrive account and allow the acquired data to be automatically transferred to the cloud. Analysts anywhere on the globe can get immediate access to the data, making collaborative work easier than ever before.

ACQ

During a turnaround, time is of the essence. The Magnifi Acquisition (ACQ) licence supports all required functionalities to maximize collection of high-quality data on heat exchanger tubing inspections with conventional technologies (ECT, RFT, NFT, MFL, and IRIS). ECT acquisitions are now powered by AI modules introduced in Magnifi 5. AI detection during acquisition can instantly ensure the entire tube length data collection for improved data quality.

CPN

Built with the same intuitive interface, Magnifi Companion (CPN) allows desktop analysis of any data acquired with the Reddy unit. Analysts can be up and running in next to no time, with larger data layouts at their fingertips. Whether CPN is used to plan and setup inspections for several instruments or to review field data, operators can take full advantage of Reddy’s industry leading capabilities.

Cloud-based License Key

Maximize utilization and flexibility with Eddyfi Technologies’ cloud-based licensing system. Software licenses are now activated in seconds and can be easily shared among your team. Gone are the days when the dongle could get lost, broken, or need to be shipped weeks in advance with the equipment.

- {{item.moduleNameDisplay}}

- No results found

- View more results

-

{{group.moduleNameDisplay}}

- No results found