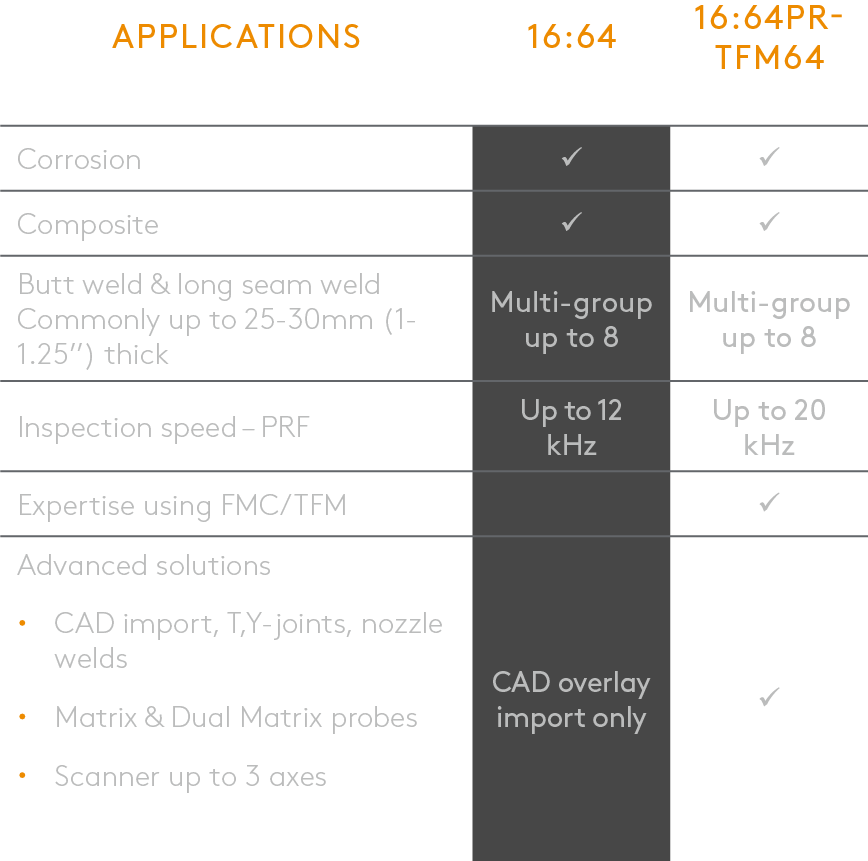

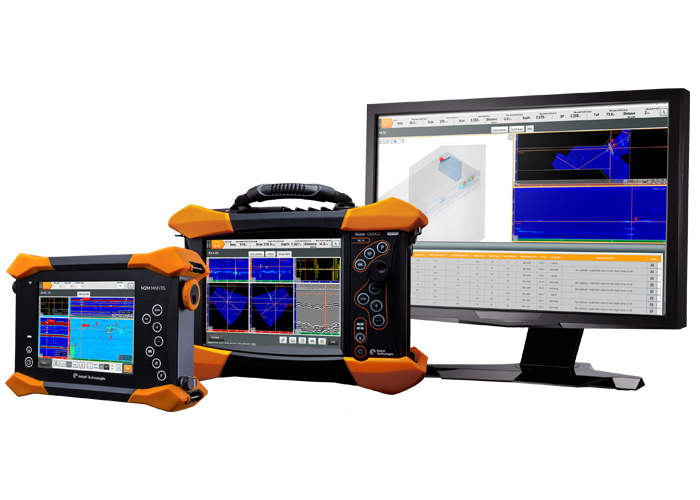

MantisTM is a robust and lightweight flaw detector offering UT, PAUT, TOFD, and TFM through the streamlined user interface called CaptureTM. Based on a 16:64PR architecture with two different models, Mantis addresses both general and advanced applications without compromising productivity.

Details

Made for the Field

- Portable, reinforced robust casing designed for IP65

- Compact and light for easy operation

- Resistive touch screen technology (glove compatible, not dust/water sensitive)

- High storage capacity – 128GB SSD

- IPEX PA, LEMO-00 UT and LEMO-16 encoder connectors

- Embedded Easy Latch adaptor available

- One internal battery + one hot-swappable battery

- Connectivity with WI-FI, USB 3 and Gbit Ethernet

Drop Test

Water Test

Upgrade options are available for the Mantis-16:64.

We recommend Gekko® for thick components and/or attenuative materials.

Designed for Your Inspection

- 16:64PR architecture plus two UT channels verified with international standards

- Compatible with existing phased array probes (linear, dual linear, and dual matrix array) and existing scanners (up to three encoder axis)

- Embedded focal law calculation (sectorial, linear, compound) on all parts through Capture software

- Up to eight group configurations

- High inspection speeds thanks to PRF up to 20 kHz

- Real-time FMC/TFM with up to 64 elements for code compliant inspections

Ecosystem, powered by Capture

- Capture-GO embedded, with advanced analysis tools (auto-sizing, 3D data display, stitching)

- Ideal for quick set-up, inspection, analysis, and reporting, covering your complete inspection task

- Capture PC versions available for set-up design and analysis

- File compatibility with Gekko

- Connectivity for remote support or remote inspection (Wi-Fi™, USB 3.0 and Gigabit Ethernet)

Solutions

Ready to discover how Mantis could work for you? Let us know!

Corrosion Mapping

R-Scan Array - Semi-automated Corrosion Mapping Solution

R-Scan Array PAUT system is the perfect solution for the inspection of complex geometry components, including curved surfaces, flat plate, pipelines, and restricted access areas. The versatile, battery-operated, semi-automated Phased Array (PA) corrosion mapping solution with onboard data collection capabilities delivers improved inspection dexterity and accuracy. more information on R-Scan Array

RMS PA - Automated Corrosion Mapping Solution

RMS PA and Mantis to provide a high-speed, remote-access ultrasonic phased array inspection system with live TFM.

It is designed to assess the condition storage tanks, pipelines, pressure vessels, and other critical equipment. It fits well in inspection programs supporting integrity management processes, ensuring effective and safe operation. more information on RMS PA

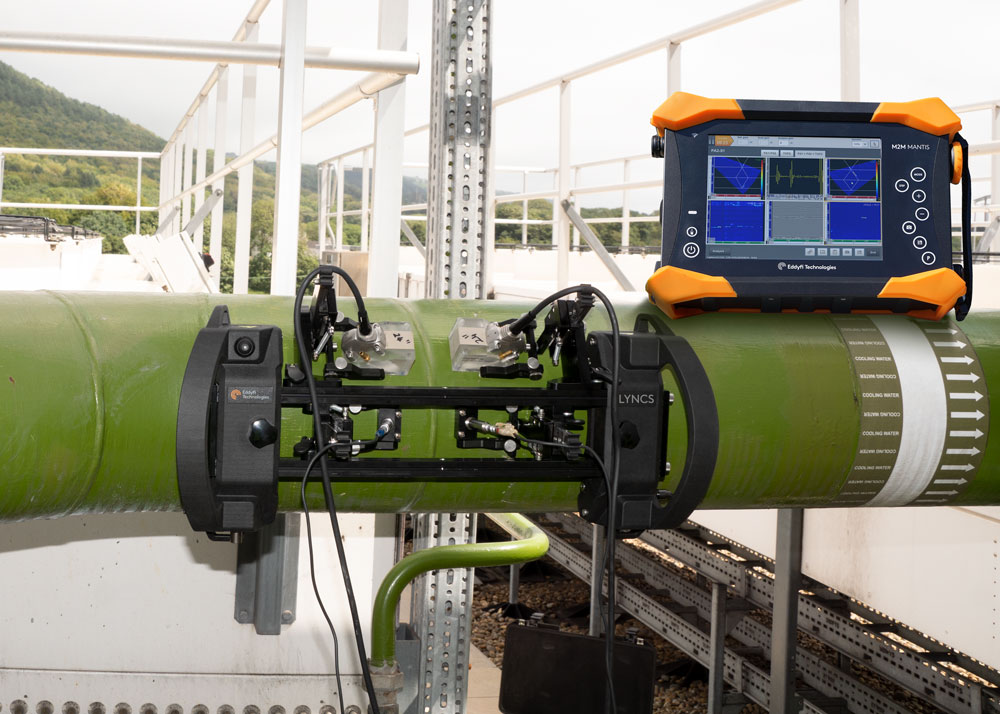

Weld Inspection with PAUT and ToFD

Mantis can perform weld inspection of simple and complex geometry components, including curved surfaces, flat plate, pipelines, and restricted access areas. The import of custom CAD overlay simplifies the analysis and can reduce false calls.

Whatever your inspection procedure, Phased Array, ToFD, and TFM are available and can ensure the Probability of Detection you need.

Exclusive Content

Workshop Capture 3.2 for welds

Pause-café avec Eddyfi | Inspection de soudures à l’aide d’une configuration multigroupes TFM

Coffee Break presented in French

Performance des outils d’analyse Capture pour l'inspection de soudures (PAUT, TOFD et TFM)

Workshop presented in French.

Ultrasons multi-éléments et TFM : puissance combinée pour l'inspection de structures critiques

Workshop presented in French.

Life is better with TFM: How can the game-changing method enhance your inspections in real-time

In this Webinar, you’ll learn:

- How Eddyfi Technologies, as TFM pioneers, implemented new options for real-time TFM in its instruments (such as plane wave imaging -PWI-, etc,),

- How this cutting-edge NDT technique can enhance your NDT inspections

- How codes and standards are accounted for directly in the system to guarantee the compliance of all setup parameters

- How intuitive and easy it is to use TFM within the Capture software, especially with 3D and toolbox analysis.

The webinar includes a presentation of the technique, illustrates the power of the Capture interface, features a demo portion and addresses some of the most frequently-asked questions.

How to simplify welds NDT inspection using Total Focusing Method (TFM) and Phased Array UT (PAUT)

Girth-weld inspections require numerous parameters to be specified on most flaw detectors. The Gekko and Mantis user interface (Capture) solves these challenges. Using off-the-shelf probes, the NDT inspector can quickly configure his unit, scan, and analyze the collected data with confidence.

In this Webinar, you’ll learn:

- How fast Capture makes it easy to get ready to scan using ultrasonic techniques such as Total Focusing Methods (TFM) and Phased Array (PAUT), how streamlined is the analysis of TFM data and how chosen approaches compare

- How adding TFM to a PAUT unit overcome limitations of each technique

- A case study: girth-weld inspection setup, data acquisition, and analysis overview

Weld Inspection Paparazzi | World Pipelines Article

This exclusive content discusses the use of ultrasound imaging techniques for inspecting pipe welds of varying conditions.

Specifications

Instrument

311 × 220 × 95 mm (12.2 × 8.6 × 3.7 in)

4.2 kg (9.5 lbs)

4h (hot-swappable battery)

8.4‘’ high contrast resistive screen

1024 × 768 px

128 GB SSD

IP65

-10°C - 45°C (14°F - 113°F)

-10°C - 60°C (14°F - 140°F)

According to MIL-STD-810G 1